Sandridge Partners

Lemoore, CA

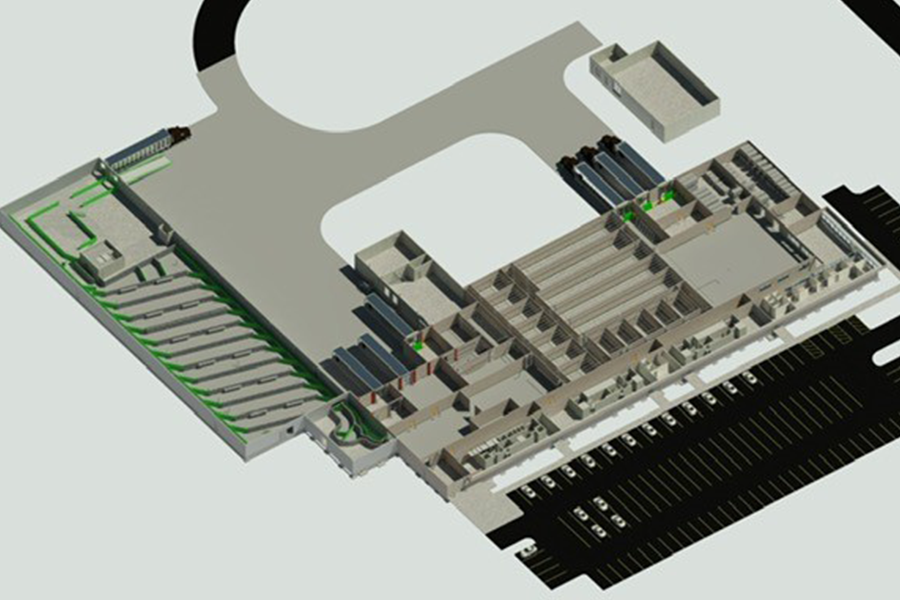

Sandridge Partners located in California is a new company formed to process their cattle. Facility Design Group was hired to provide detailed engineering and construction documents for the cattle processing and cutting operation of 90,000 square feet. The design included cattle holding pens, dirty and clean kill, offal processing, hot boxes, carcass holding, cut floor and cold storage areas.

The livestock holding area was planned to receive and temporarily house animals in preparation for slaughter. The holding pens were sized based on 20 square feet per head. The crowd pen and chute with driver walkway was provided to funnel cattle into the appropriate lead-up irons and restrainer in an orderly manner.

The slaughter system provided was planned to be a single evisceration line system, to operate at a design (chain speed) output capacity of 30 cattle (or head) per hour.

The design considered all steps necessary to handle the kill rate from the cattle holding barn, dirty and clean kill area, edible and inedible offal, hot boxes to reduce the animal temperature from 107F to 50F over 24-hours prior to carcass placement via the overhead rail system in the carcass holding chambers that reduce the animal temperature over the next 24 hours from ~50F to 35F degrees at constant air flow 20 LF/Min with relative humidity 85 to 90%. Separate aging carcass chambers are provided to allow product aging.

Once the cattle carcasses have been tempered in the carcass holding cooler, they are transferred via overhead rail conveyor to the cut floor. All incoming products are received, manually separated, and trimmed prior to packaging.

Once portioned, the product will be vacuum packaged, boxed and stored in the finished product cooler for subsequent sale.