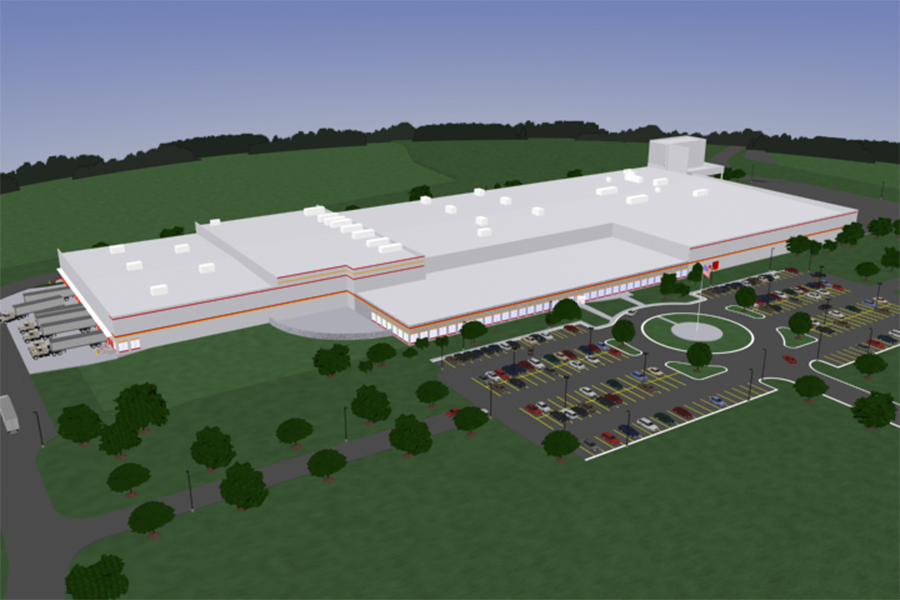

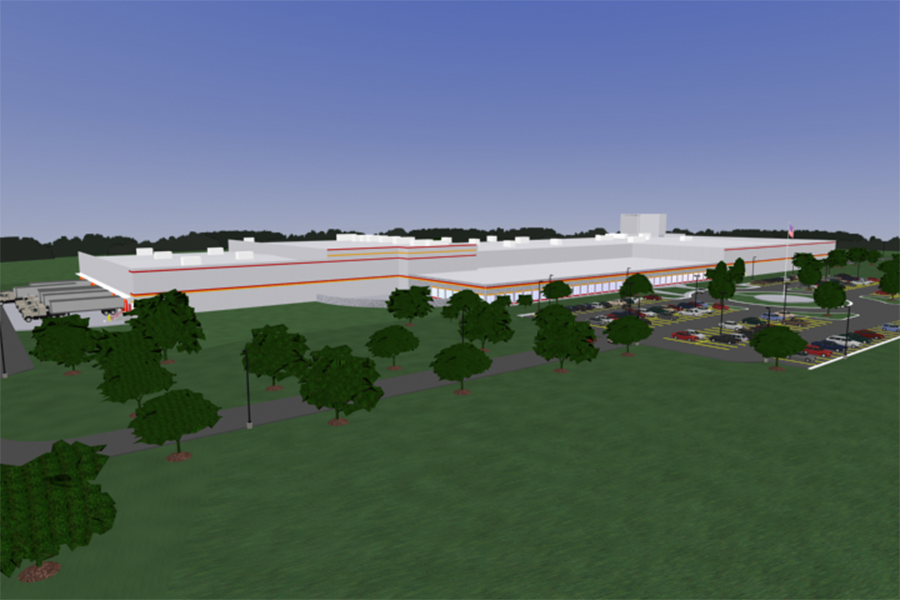

Pepperidge Farm

GREENFIELD BAKERY

Bloomfield, CT

290,000-SF greenfield “hot” bakery project. Modernization and strategic location analysis drove this project. Three new production lines and one relocated production line would produce a variety of baked bread products.

Unit operations for the project include bulk material receiving, storage silos, pneumatic transfer of material, major-minor handling systems, mixing, proofing, baking, wrapping, packaging and storage.

The central utilities corridor doubled as a visitor gallery, allowing viewing of the various production areas without having to enter the processing space.

Two mixing operations per line allow for maximum efficiency for the overall line. Automated pan handling and basket washing limited the need for too much labor associated with these activities.

Centralized utilities were planned for individualized metering on a per line basis. This information was fed back to the central control room for reporting and control.